Quality Control

Procedures, Systems

Inventive Label has developed the proprietary Flexo Edge order processing system that insures all key production elements are communicated and verified from one process stage to every other stage, and from one order to future repeat orders. Label graphics are assigned numerical tracking codes to guarantee proper copy integrity, addressing client revisions, and fail-safe production line clearances. We abide by a set of ISO based procedures spanning the complete order process, from order entry, through production, to order packing and shipping. Whether it be high-end cosmetic label printing or onserted hang tag printing, the quality is inbred into every label.

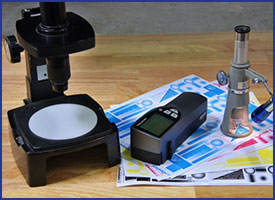

Diagnostics

Inventive Label uses state-of-art QC instruments to insure compliance with client expectations for their product labeling. For example, color control is monitored at the time of ink formulation as well as the printed stage. Spectrophotometer analysis sets strict “pass-fail” criteria and allows for appropriate in-process adjustments. Complex constructions are subjected to environmental testing such as abrasion resistance and accelerated aging trials, using time-tested aging oven techniques. Even simple testing such timed water immersion for wine labels is part of the testing procedure when appropriate.