Label cutting dies (tooling) come in a wide variety of formats. In the past, tooling was made on manual turning and milling machines. It was an expensive process to produce cutting dies with custom label shapes or other specialty tooling. Often labels were formed using straight cross cut blades and rotary cutters (pizza wheels) to trim the sides. With today’s CNC lathes and mills, tooling can be made in nearly any size and shape. Here at Inventive Label, we have the capability to make custom shaped labels as small as 1/4”, all the way up to 13” X 24” rectangles.

There are limitations though. While a shape can technically have square or sharp corners, it is best to allow at least 1/64” radius corners, and preferably 1/32” radius corners. Another limitation is that the cutting blades’ height needs to be tuned to the material thickness being cut. Even though there may be a 4” X 6” rectangle in inventory, it may be tuned to cut to a standard 40# SCK paper liner and will fail when attempting to cut a label with a 1.2 mil polyester liner. A new tool, designed to cut the chosen material, will be required. In another circumstance, a tool that is tuned to cut a single layered prime label, may fail to properly cut a 12 page booklet label.

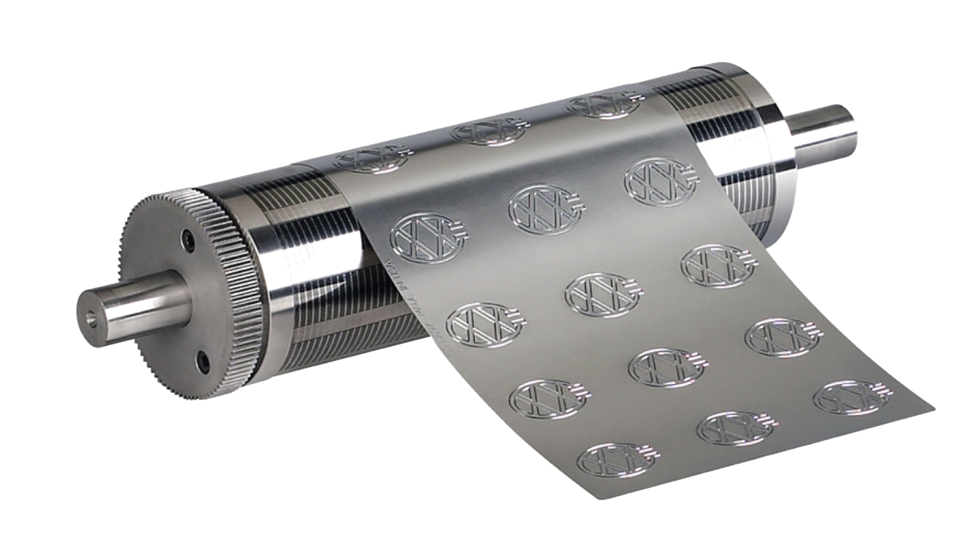

Many label print jobs require a standard solid rotary cutting tool that starts as a solid piece of metal and is turned and milled to the size and shape required. Some jobs, however, are perfectly suited for a much more economical “flexible” cutting tool. This type of tool is a thin, flexible sheet of metal engraved with the shape of the label. This sheet is then wrapped around a reusable magnetic cylinder of the correct diameter. Each magnetic cylinder can be used to cut an unlimited number of differently shaped labels. Inventive Label has a large inventory of magnetic cylinder sizes. This allows us to choose the very best tool for the job and thereby greatly reducing the cost of tooling for your job.