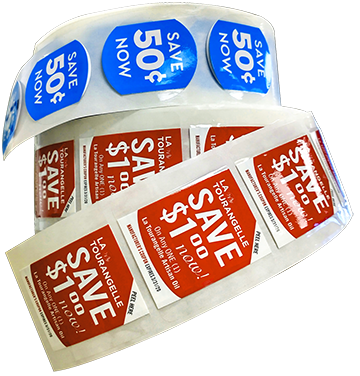

Folded labels are one of the most versatile Extended Content Labels (ECL’s) that exist. They are used extensively for Instant Redeemable Coupons (IRC’s). These fold-out coupons can frequently be seen at the grocery store promoting $2.00 off some hot dogs or some other item. Folded labels are also often used for multi-lingual products. Each fold-out panel can have the usage instructions in many different languages on the same product container, thereby eliminating the need for separate labels being produced for each language. Folded labels also work well for safety and other regulatory information, as this usually requires extra space for the wording.

Folded labels can be produced in a huge variety of configurations, from simple 4 panel half folds to booklet labels that may have 40 pages or more. The most cost effective folded labels are produced as inline folded roll-form labels. This construction is produced as a single press pass, with the raw paper material being printed on both sides, then folded and finally affixed to a pressure sensitive base label. Very efficient, very cost effective.

Inline folded labels can be produced in nearly any shape, (e.g. rectangles, circles, ovals, even custom shapes). Inventive Label, Inc. has even produced folded labels in the shape of lips for a cosmetic company. The number of panels (pages) for an inline folded label can be anywhere from 2 to 32. The final label size can be as small as 3/8” to more than 12”.

Onsert folded labels are the most versatile. Onsert labels are produced by affixing a pre-printed, pre-folded piece to a base label as a separate press operation. As mentioned above, they can range from 2 panels to more than 40. Onsert labels can also be folded in many different patterns, (e.g. accordion folded, roll folded, etc.). Also, they can be produced having a spine glued to the base similar to a book. As you can imagine, onsert labels are a very specialized type of label and require a good deal of expertise to produce.

Of course, both onsert and inline folded labels can have a clear pressure sensitive base label or be white with printing on the base label. Both types can also have a release coating which facilitates the re-closure of the label for multiple openings and closings.